We provide optimal processes and carefully selected machines according to the characteristics and requirements of the paper to be produced. The process is designed and applied suitably for its intended application, considering various kinds of raw materials.

The general process consists of the following partial processes, along with the related machines to meet paper production requirements.

OCC Stock preparation

-

01

With over 40 years of experience

With over 40 years of experience in the OCC line, our products are one of the solutions for energy-saving and reliable recycling of waste paper.

-

02

OCC Total solution

We approach OCC Total solution not only at the product level but also across the entire process.

-

03

Advantages with GSPT

We offer an ideal process of OCC line, minimal energy consumption and high-quality machines.

-

04

Smart automation

The lines are fully automated and managed through our advanced control system.

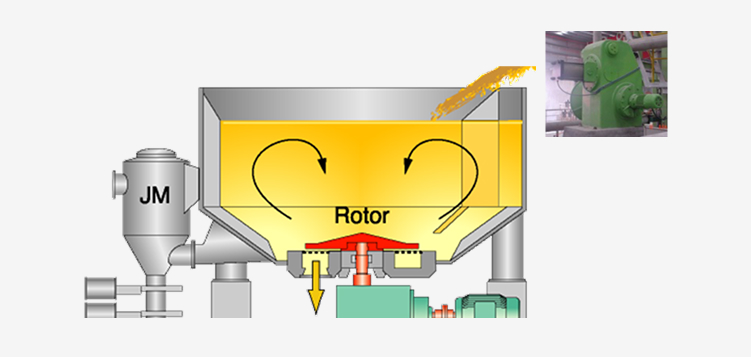

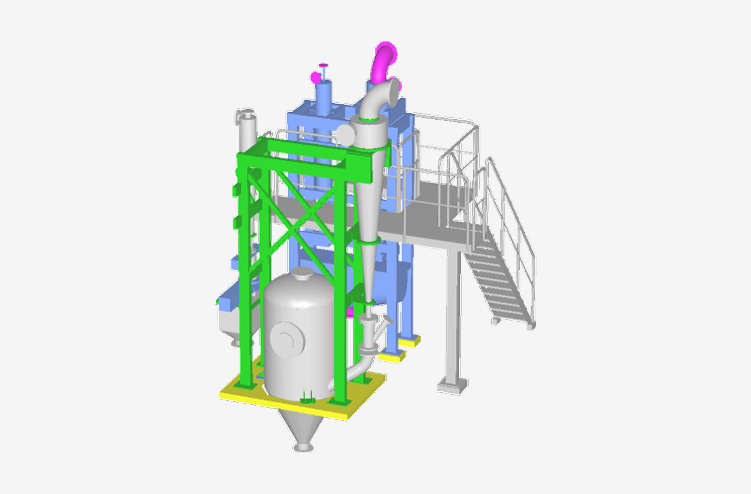

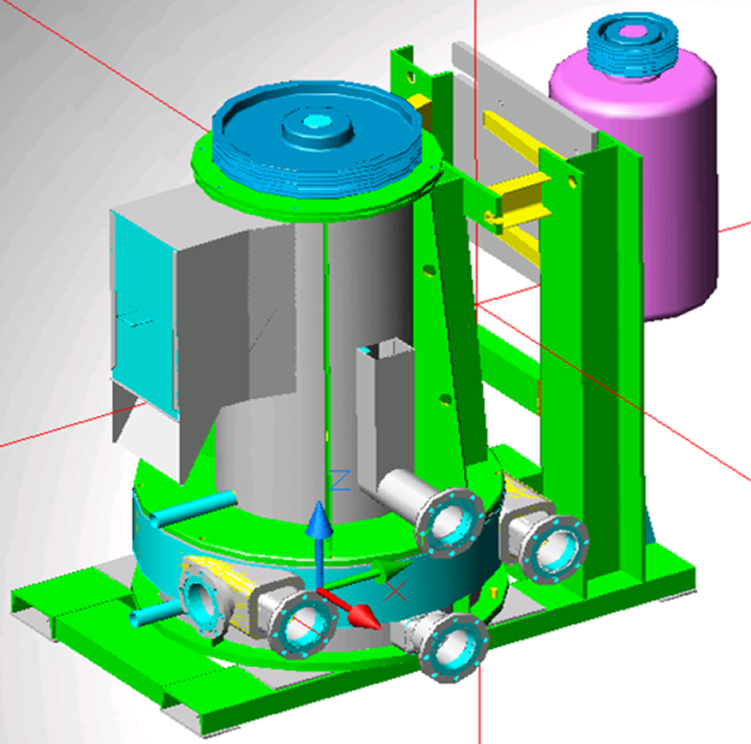

- Pulper

- Secondary pulper

- Drum screen

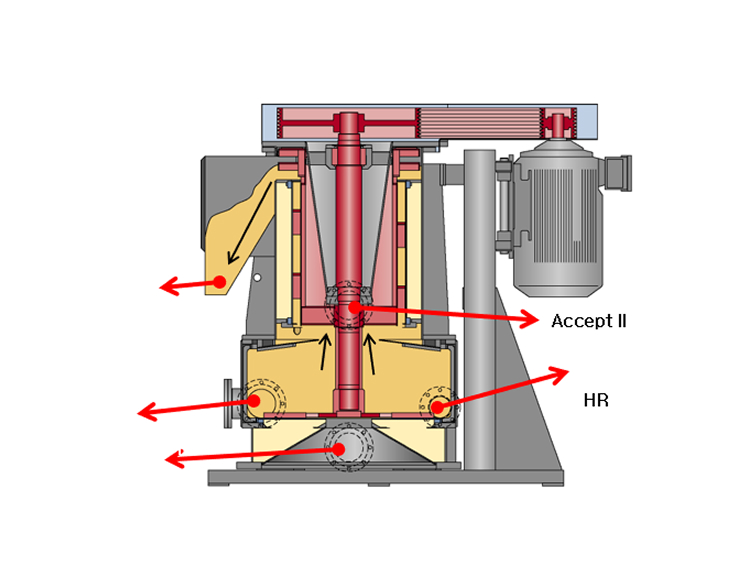

- 2 stage cleaner

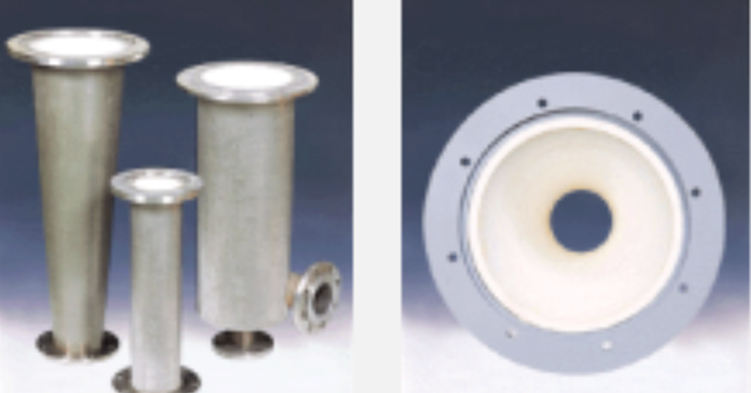

- LC cleaner

- MC Screen

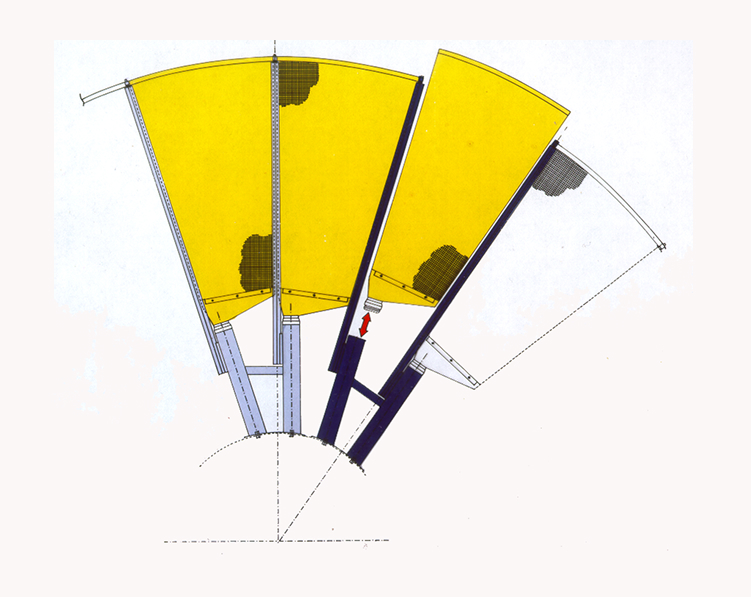

- Disc Screen

- Double sorter

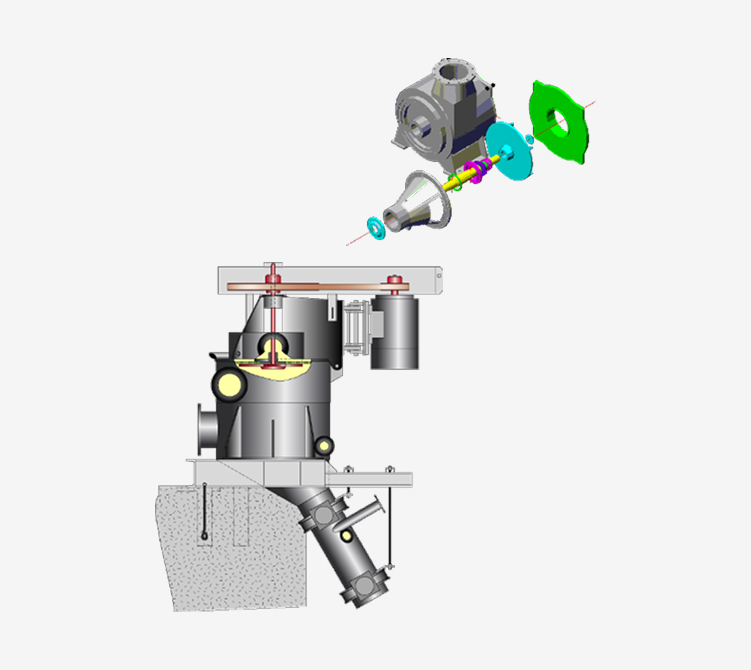

- Fine Screen

- Disc Filter

- Approach Screen

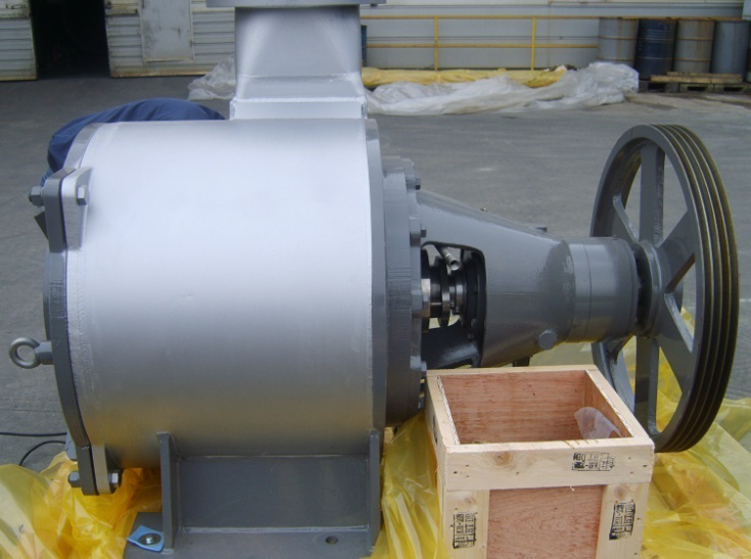

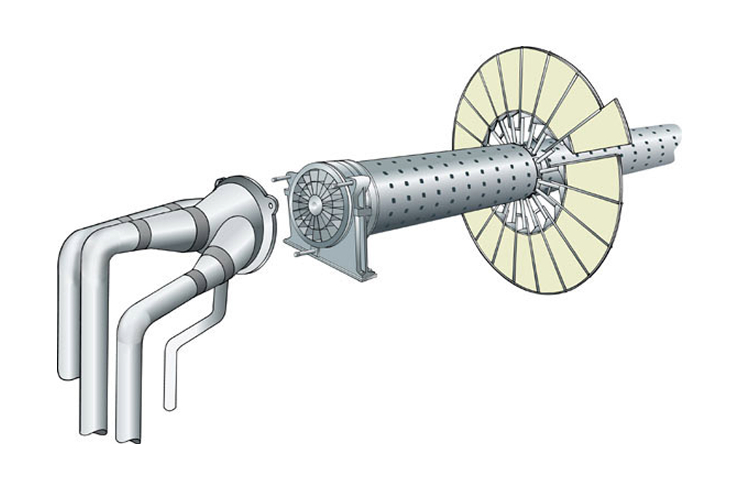

- Deflaker & D.D Refiner

- Disc Thickener

- Under Pulper

- Feeding the law material as bale wire cut

- Early separation of contraries at beginning of process

- Trouble free continuous operation

- Wear resistance construction (screen plate & rotor position)

- Energy saving effect over 20%

- Additional production

- Periodical operation

- Washed out contaminants to Screen drum -- fiber saving

- Gentle separation fibers and contaminants

- No size reduction of contaminants

- Wear resistance construction

- Easy installation

- Drum is driven through geared motor

- The Perforated drum of SUS304 Outlet chute of SUS304 Supportin structure of Mild steel

- Shower pipe with Nozzle of SUS 304

- Wear resistance construction

- Compact Design

- Continuous reject discharge flow from H.C. Cleaner

- Improved Cleaning efficiency in smaller particle size range below 0.5mm diamether (by LC Cleaning, 2nd Stage)

- Shorter heavies retention time in H.C. Cleaner

- Longer service life of down stream screen (approx. 4X)

- Wear resistance construction for separation cones, bottom

-

Up to 2% feed consistency operation

- with comparable cleaning performance in conventional hydrocyclones at 1%

- Superior cleaning performance over the entire operationg consistency range

- Up to 50% lower applied energy

- Considerably lower reject rates than conventional hydro cyclones

-

Lower specific energy consumption

- Energy saving effect, approx. 20%

- Crossing the rotor elements to prevent from plugging of Screen basket

-

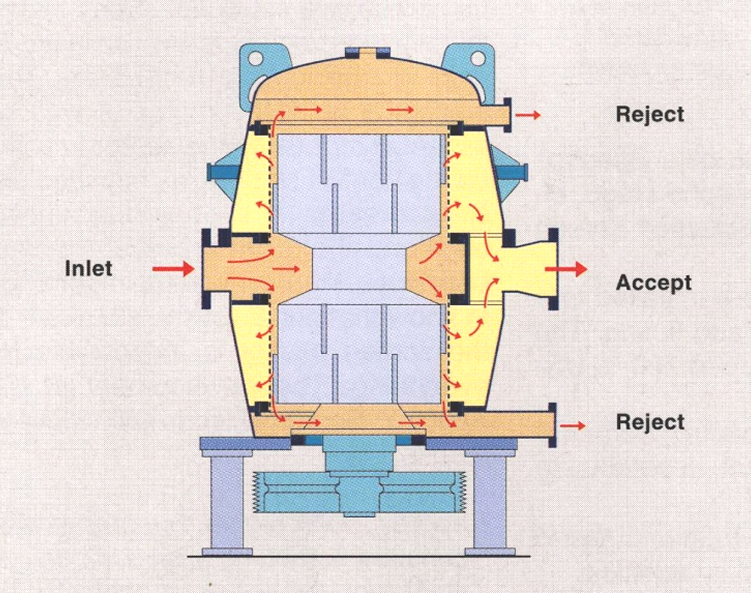

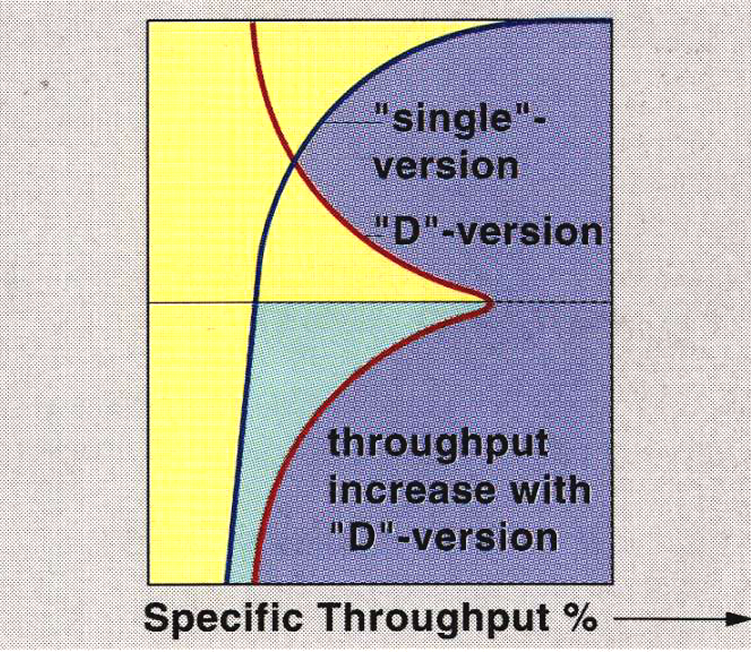

Higher thoughtput with constant screening area and space

- Approx. 30% higher

- Higher Deflaking effect

- Low vat volume

- Higher specific power density

- Deflaking bars on cover & S/N plate

- Wear resistance construction

- Conical shape vat

- No re-circulation of heavy weight particles inside the vat

- Additional production

- Forwrd arrangement (Presureless unit)

- Gentle separation & discharge of the foreign particles

- Screen basket for rejects removal

- High reject discharge dryness

- Fiber-free rejects discharge with high final dryness more than 20%

- Wear resistance construction

- The bottom housing is lined with wearing materials, Basalt tiles

- Continuous heavy rejects discharge

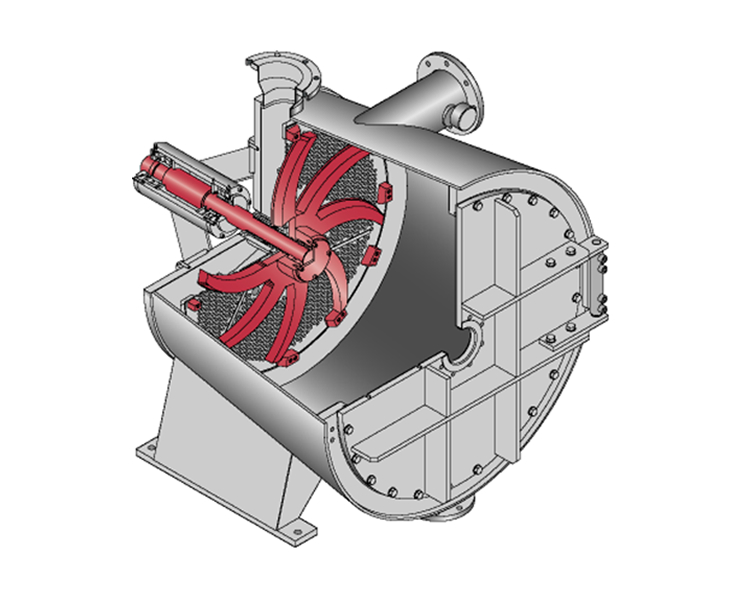

- Multi vane Foil rotor

- Gentle screening with low energy consumption

- Low resultant turbulence

- High efficiency for the stickies removal

- Screen Basket

- No Sharp edge - No milled surface

- Large free screening area (30%↑)

- Extreamly close slot width tolerance

- Excellent screening efficiency - Low rotor speed

- Process solutions

- Thickening & fibeer recovery

- Mechanical strengths

- Environmental impact

- High Screening efficiency

- Taper shape chamber

- Even flow through screen basket

- Low rotor speed

- Low pulsation

- Cross arrangement of vane on rotor

- Low energy consumption

- Large free screening area

- Good fibrilization and Uniform fiber freeness

- Hydraulic self-aligning Rotor

- Gap adjustment by electro geared motor > no additional hydraulic system for gap-adjustment

- Easy maintenance

- Extremely compact design for small space

- Quality of filtrate water

- Efficient and reliable dewatering

- Easy and simple operation and maintenance